German screw compressor manufacturers order four Rochdale-built PTG Holroyd machines

Date published: 19 July 2023

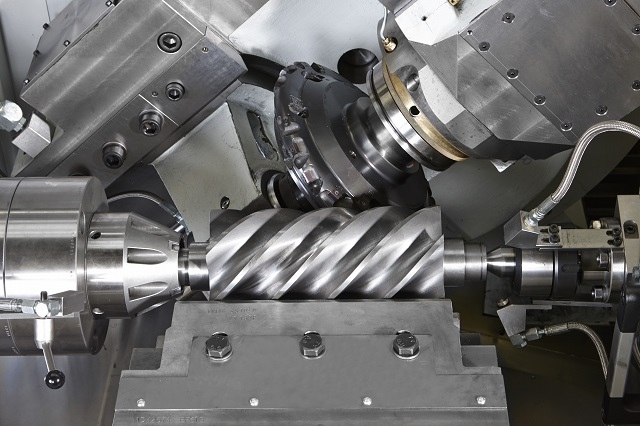

PTG Holroyd 3EX-R rotor milling machine

In just one week, Rochdale-based PTG Holroyd has secured orders for four of its specialist rotor milling machines.

The orders for the two German-based screw compressor manufacturers will be shipped during 2024 and their combined value is in the region of £5 million.

Two of the EX Series CNC machines are destined for a leading producer of screw compressors for refrigeration applications, whilst the other two have been ordered by a specialist in screw compressors and energy efficient blowers.

PTG Holroyd sales director, Mark Curran said: “PTG Holroyd’s EX Series rotor milling machines have long been renowned for their performance, precision, reliability and repeatability, regardless of whether they are producing highly complex components with helical screw profiles, or milling worms and gear parts.

“Never content to rest on our laurels, however, we have added some key upgrades to the entire EX Series range – perhaps the most significant of which is the use of the Sinumerik ONE future-proof CNC from industrial automation specialists, Siemens.”

Mr Curran continued: “Our positive experiences of using the Sinumerik ONE CNC for the HG350 grinding machine range, combined with excellent customer feedback, confirmed our decision that it was the right control for our upgraded EX Series of rotor milling machines.”

By working in close collaboration with Siemens, PTG Holroyd has also been able to incorporate the ‘Create my virtual machine’ and ‘Run my virtual machine’ software capabilities of the Sinumerik ONE suite into its EX Series machines.

Used in tandem with its own internal machine design packages, these capabilities enable PTG Holroyd to create a virtual ‘digital twin’ of each new EX Series rotor milling machine on the desktop, before ordering components and commencing a physical build.

Virtual rotors or worm helix profiles can be cut – all while observing entire simulated manufacturing cycles, and testing safety and failsafe features.

Mr Curran added: “By first creating each customer’s specific machine requirements virtually, physical build time is reduced – something which, in turn, helps us to remain exceptionally competitive in these cost-conscious times.

“The Sinumerik ONE software also makes acceptance testing incredibly straightforward, as our customers are able to sign-off on their new machine before it has even been built.”

Do you have a story for us?

Let us know by emailing news@rochdaleonline.co.uk

All contact will be treated in confidence.

Most Viewed News Stories

- 1First full Stalking Protection Order against a child in UK secured for family in Heywood

- 2Legal challenge against recently approved development masterplan to build 165,000 homes in Greater...

- 3Lottery Winners and Heather Small announced as headliners for Rochdale Feel Good Festival

- 4New energy facility with the ability to power 20,000 homes approved in Bamford

- 5Roadworks, temporary local road closures and restrictions

To contact the Rochdale Online news desk, email news@rochdaleonline.co.uk or visit our news submission page.

To get the latest news on your desktop or mobile, follow Rochdale Online on Twitter and Facebook.